|

|

| Brand Name: | Santon |

| Model Number: | Customized |

| MOQ: | 50 |

| Price: | Negotiable |

| Packaging Details: | plastsc box |

| Payment Terms: | L/C, T/T, Western Union |

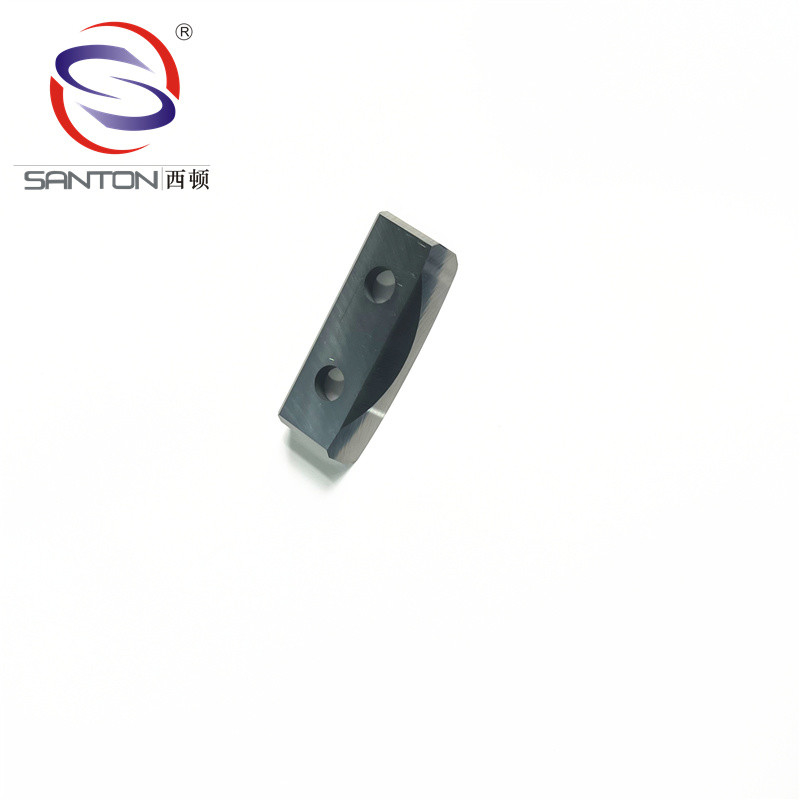

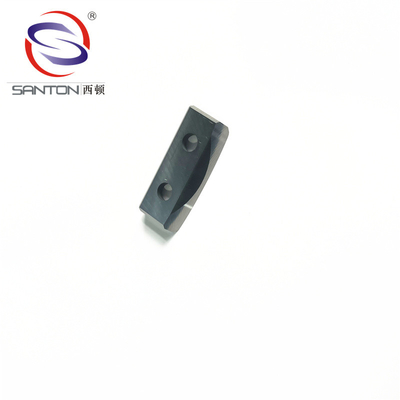

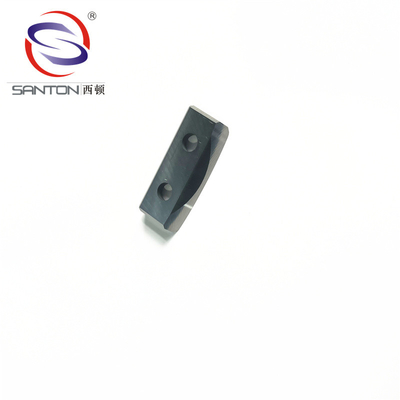

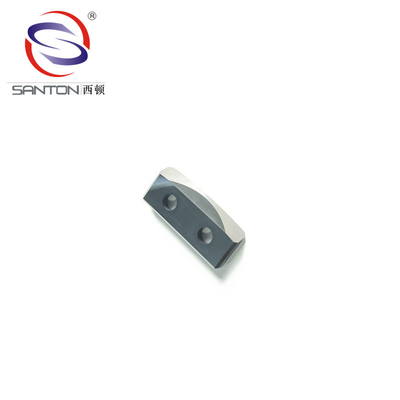

Tungsten carbide hartmetall insert for areospace customized models

Product Description:

High strength, good impact resistance and impact strength. Suitable for rough skin turning, milling finish carbon steel, and alloy steel during continuous cutting, and semi-finishing and finishing turning during interrupted cutting.

Best strength, high impact and shock resistance between W-Co-Ti alloys, but relatively lower wear resistance. Suitable for rough skin turning, rough planning, and semi-finishing planning of carbon steel, and including forged alloy steel, stamped parts, and the cast iron surfaces during intermittent cutting.

![]()

Grade Information

| Santon grade | ISO grade | ANSI Grade | Physical and chemical properties | Performance and application | |

| TRS | Hardness | ||||

| N/mm2 | HRA | ||||

| YG6X | K15 | C3 | 1890 | 91.5 | Fine Grain toilet alloy, superior wear resistance to YG6, force near YG6. Suitable for processing alloy chilled cast irons, and refractory alloy steel, as well as finishing of ordinary cast irons. |

Company Information

Santon alloy is a focus on the carbide cutting blades research and development, production, sales in the integration of high and new technology and new materials enterprises, the company's main products are made with the blade, nc blades, PCD/CBN matrix and aluminum processing blade four series, can provide users with rich technology content and the application value of the pre-sale, sale and after-sale service. The vertical blade series products are the core products of the company's strategic development, positioning as "high-end, alternative to import".

We can manufacture small and large scale carbide products as per your drawing. Our in house technicians and experts are quite qualified in this field with over 20 years of experiences. We are a customer focused, innovative and value driven company which manufactures and supplies cemented carbide products to their valuable customers at affordable price.

![]()

![]()

![]()

Certifications

![]()

FAQ

Q. Are you a manufacturer or a trading company?

A. We are a professional manufacturer with 10 years of experience of producing and selling carbiede inserts.

Q. What is your main products?

A. Our main products includes cemented carbide plates, strips, blanks, saw tips, geological and mining bits, brazed tips, indexable carbide inserts, wear parts,snow plow inserts, tungsten carbide pins, etc.

Q. what's the payment term?

A. We accept Western union, Onetouch, T/T, and L/C. 30% T/T deposit and 70% balance before shipment, or against copy of BL, or L/C at sight.

Q. What about your delivery time?

A. Usually it will take about 25 - 30 days for production.But for new molds, the lead time may need 10days more to open molds. If you need the goods urgently, we could try to push for and shorten the delivery time.

Q. What is your minimum order quantity(MOQ)?

A. No limit for MOQ. For non-standard products, mold fee need to be paid, but can be refunded later.

Q. What is your warranty?

A. We extend a 100% satisfaction guarantee on all items. if you’re not completely satisfied with our products ,we’ll replace them or refund the fee

Q. Where is your market?

A. Our products are popular in Germany, America, Mexico, India, Russia, Indonesia, Malaysia, Bangladesh, South Africa,etc.

|

| Brand Name: | Santon |

| Model Number: | Customized |

| MOQ: | 50 |

| Price: | Negotiable |

| Packaging Details: | plastsc box |

| Payment Terms: | L/C, T/T, Western Union |

Tungsten carbide hartmetall insert for areospace customized models

Product Description:

High strength, good impact resistance and impact strength. Suitable for rough skin turning, milling finish carbon steel, and alloy steel during continuous cutting, and semi-finishing and finishing turning during interrupted cutting.

Best strength, high impact and shock resistance between W-Co-Ti alloys, but relatively lower wear resistance. Suitable for rough skin turning, rough planning, and semi-finishing planning of carbon steel, and including forged alloy steel, stamped parts, and the cast iron surfaces during intermittent cutting.

![]()

Grade Information

| Santon grade | ISO grade | ANSI Grade | Physical and chemical properties | Performance and application | |

| TRS | Hardness | ||||

| N/mm2 | HRA | ||||

| YG6X | K15 | C3 | 1890 | 91.5 | Fine Grain toilet alloy, superior wear resistance to YG6, force near YG6. Suitable for processing alloy chilled cast irons, and refractory alloy steel, as well as finishing of ordinary cast irons. |

Company Information

Santon alloy is a focus on the carbide cutting blades research and development, production, sales in the integration of high and new technology and new materials enterprises, the company's main products are made with the blade, nc blades, PCD/CBN matrix and aluminum processing blade four series, can provide users with rich technology content and the application value of the pre-sale, sale and after-sale service. The vertical blade series products are the core products of the company's strategic development, positioning as "high-end, alternative to import".

We can manufacture small and large scale carbide products as per your drawing. Our in house technicians and experts are quite qualified in this field with over 20 years of experiences. We are a customer focused, innovative and value driven company which manufactures and supplies cemented carbide products to their valuable customers at affordable price.

![]()

![]()

![]()

Certifications

![]()

FAQ

Q. Are you a manufacturer or a trading company?

A. We are a professional manufacturer with 10 years of experience of producing and selling carbiede inserts.

Q. What is your main products?

A. Our main products includes cemented carbide plates, strips, blanks, saw tips, geological and mining bits, brazed tips, indexable carbide inserts, wear parts,snow plow inserts, tungsten carbide pins, etc.

Q. what's the payment term?

A. We accept Western union, Onetouch, T/T, and L/C. 30% T/T deposit and 70% balance before shipment, or against copy of BL, or L/C at sight.

Q. What about your delivery time?

A. Usually it will take about 25 - 30 days for production.But for new molds, the lead time may need 10days more to open molds. If you need the goods urgently, we could try to push for and shorten the delivery time.

Q. What is your minimum order quantity(MOQ)?

A. No limit for MOQ. For non-standard products, mold fee need to be paid, but can be refunded later.

Q. What is your warranty?

A. We extend a 100% satisfaction guarantee on all items. if you’re not completely satisfied with our products ,we’ll replace them or refund the fee

Q. Where is your market?

A. Our products are popular in Germany, America, Mexico, India, Russia, Indonesia, Malaysia, Bangladesh, South Africa,etc.